9 Hidden Safety Risks That Sabotage Warehouse Operations (And How AI Solves Them)

Warehouse injuries cost U.S. businesses over $15 billion annually, but the real damage runs deeper.

When experienced workers are sidelined by preventable accidents, entire operations suffer from knowledge gaps and productivity losses that can take months to recover from.

A report conducted by The Strategic Organizing Center (SOC) on the injury crisis of Amazon workers from 2022 – 2023, shows a chilling insight of what truly happens in warehouses.

“In 2022, there were 38,609 total recordable injuries, defined as those requiring medical treatment beyond first aid or requiring time off a worker’s regular job at Amazon facilities. The vast majority of these were serious: 36,487, or 95 percent, of the injuries were categorized as either light duty or lost time injuries that is, injuries where workers were hurt so badly that they were either unable to perform their regular job functions (light duty) or forced to miss work entirely (lost time).”

This hasn’t stopped in 2025.

In fact, despite extensive safety programs, workers get injured on a regular basis, making it impossible to ignore every once in a while seconds in warehouse operations across America. The solution isn’t just better training or more safety meetings, it’s leveraging AI in warehouse management to identify and prevent risks before they lead to incidents.

The Modern Warehouse Safety Challenge

Today’s warehouses operate at unprecedented speeds and scales that traditional safety approaches simply can’t match. With facilities running 24/7, hundreds of workers across multiple shifts, and complex equipment interactions, human oversight alone isn’t enough to maintain consistent safety standards.

The problem isn’t lack of commitment to safety, it’s the fundamental limitations of manual monitoring. Safety managers can’t be everywhere at once, inspections miss hazards that develop between rounds, and incident reports only reveal problems after someone gets hurt.

This is where AI in warehouse automation transforms the safety equation, shifting from reactive incident response to proactive risk prevention.

9 Hidden Safety Risks Sabotaging Your Operations

1. Loading Dock Blind Spots

The Hidden Risk: Loading docks account for 40% of warehouse injuries, with pedestrian-equipment interactions happening too fast for human monitoring to prevent.

How AI Solves It: Computer vision systems provide 24/7 monitoring of dock areas, instantly detecting when pedestrians enter forklift zones or when equipment operates outside safe parameters. The use of AI in warehouse management enables real-time alerts that prevent collisions before they occur.

2. Cross-Traffic Intersection Chaos

The Hidden Risk: High-velocity zones where forklifts, pedestrians, and automated systems converge create split-second scenarios that determine safety outcomes.

How AI Solves It: AI in warehouse operations analyzes traffic patterns and predicts potential collision points, automatically triggering warning systems and route adjustments to prevent dangerous interactions.

3. Inconsistent PPE Compliance

The Hidden Risk: Personal protective equipment usage varies throughout shifts, with traditional spot-checks missing non-compliance during critical moments.

How AI Solves It: Continuous monitoring systems track hard hat usage, safety vest compliance, and proper footwear across all work areas, providing immediate alerts when workers enter hazardous zones without required protection.

4. Elevated Work Area Falls

The Hidden Risk: Fall protection compliance fluctuates during different shifts, and traditional safety checks can’t monitor continuous PPE usage on elevated platforms.

How AI Solves It: Vision systems monitor elevated work areas continuously, ensuring fall protection is properly used and alerting supervisors to potential hazards before accidents occur.

5. Chemical Spill Detection Delays

The Hidden Risk: Hazardous material exposure risks change by the minute, requiring constant vigilance that exceeds human monitoring capacity.

How AI Solves It: Environmental sensors combined with computer vision instantly detect spills, chemical leaks, or unsafe exposure conditions, triggering immediate containment protocols.

6. Equipment Maintenance Zone Violations

The Hidden Risk: Lockout/tagout procedures and safety protocols need real-time verification, not post-incident investigation.

How AI Solves It: AI in warehouse robots and monitoring systems ensure proper safety procedures are followed during maintenance, preventing unauthorized equipment access and ensuring compliance with lockout protocols.

7. Behavioral Risk Patterns

The Hidden Risk: Unsafe behaviors like improper lifting techniques, rushing near equipment, or entering restricted zones often go unnoticed until an incident occurs.

How AI Solves It: Machine learning algorithms recognize dangerous behavior patterns and provide immediate feedback to both workers and supervisors, enabling corrective action before injuries happen.

8. Environmental Hazard Accumulation

The Hidden Risk: Spills, debris, and changing floor conditions develop between safety inspections, creating slip and fall hazards.

How AI Solves It: Continuous environmental monitoring detects changing conditions instantly, triggering cleaning protocols and hazard warnings before workers are exposed to risks.

9. Shift-Based Safety Inconsistencies

The Hidden Risk: Safety standards and monitoring intensity can vary between day, evening, and night shifts due to different supervision levels.

How AI Solves It: 24/7 AI monitoring ensures consistent safety standards across all shifts, providing the same level of protection regardless of time or staffing levels.

How AI in Warehouse Management Transforms Safety Operations

The integration of AI in warehouse safety systems creates a comprehensive approach that addresses these hidden risks through:

Real-Time Risk Detection

Unlike traditional safety approaches that rely on periodic inspections, AI vision systems provide continuous monitoring of all risk areas. This constant vigilance means hazards are identified and addressed within seconds of appearing, not hours or days later.

Predictive Safety Analytics

AI in warehouse operations doesn’t just detect current hazards, it analyzes patterns to predict where incidents are most likely to occur. This predictive capability allows safety teams to implement preventive measures in high-risk areas before problems develop.

Automated Compliance Monitoring

The use of AI in warehouse management for safety compliance eliminates the gaps in manual monitoring. Systems automatically verify that safety protocols are being followed, from PPE usage to proper equipment operation procedures.

Enhanced Training and Education

AI systems provide real-world examples of near-misses and unsafe behaviors, creating powerful training tools that help workers understand risks in their specific work environment.

Privacy-First AI Implementation

Modern AI safety systems address privacy concerns through:

- Anonymous Detection: Systems identify safety risks without storing personal biometric data

- Behavior-Focused Monitoring: Technology monitors actions and conditions, not individuals

- Transparent Operation: Workers receive the same safety alerts as supervisors

- Data Protection: All safety information remains under organizational control

The ROI of AI-Powered Safety

Organizations implementing AI in warehouse automation for safety typically see:

- Lower insurance premiums and improved safety ratings

- Reduced downtime from safety incidents and investigations

- Automated compliance documentation for regulatory requirements

- Cultural shift from reactive to proactive safety mindset

Getting Started with AI Safety Implementation with Observia.ai

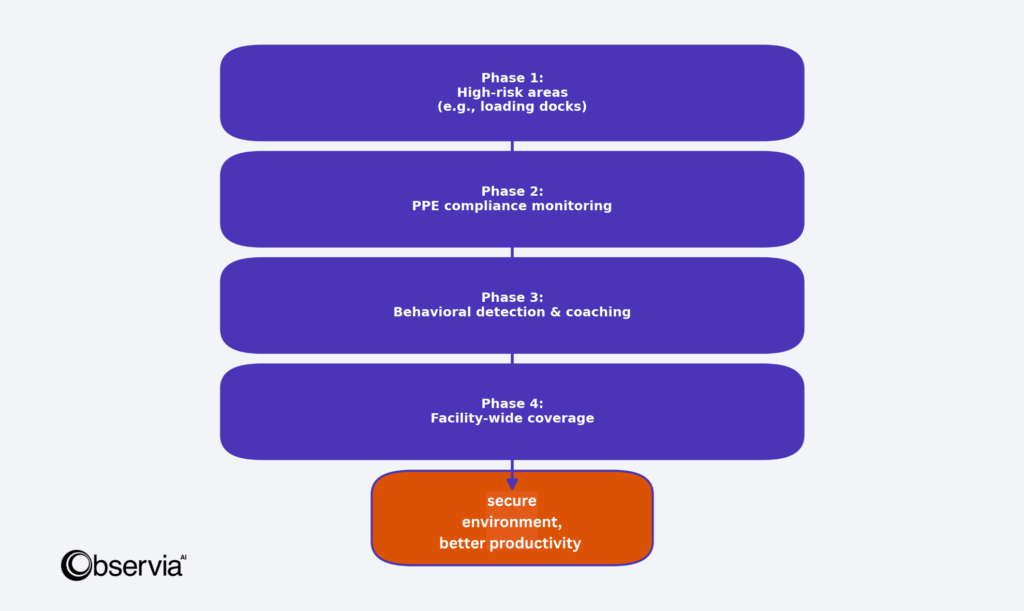

The most successful AI safety implementations follow a phased approach:

Phase 1: Start with high-risk areas like loading docks or cross-traffic zones

Phase 2: Expand to PPE compliance monitoring across key work areas

Phase 3: Add behavioral safety detection and real-time coaching

Phase 4: Scale to comprehensive facility-wide coverage.

Taking your Next Steps with Observia.ai

The question isn’t whether AI will transform warehouse safety, it’s whether your organization will lead this transformation or follow it.

At Observia.ai we believe in simpler solutions to help you take a step forward. Here is a very simple glimpse of how we plan to help you.

The technology exists today to give your warehouse the ability to see risk before it happens. The systems are privacy-respecting, worker-friendly, and designed to enhance rather than replace your safety expertise.

For safety professionals ready to explore how AI vision can transform their risk management approach, the conversation starts with understanding your specific facility challenges and risk patterns.

Ready to see how AI vision could transform safety in your warehouse? Connect with Observia.ai to explore a customized approach for your facility’s unique risk profile.